|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Last page update was 14 Jun 2020 |

|

|

|

Fisher Fury R1 Exhaust System

Manifold

Fisher Sportscars  sell a manifold for the R1 engine but it is not really designed and constructed with the same level of detail that Richard

sell a manifold for the R1 engine but it is not really designed and constructed with the same level of detail that Richard  took. As it is pre-made, you don't also have the same flexibility in placing the engine and silencer. Richard

took. As it is pre-made, you don't also have the same flexibility in placing the engine and silencer. Richard  went to Custom Fabrications to get his manifold custom made as a 4-2-1 design

went to Custom Fabrications to get his manifold custom made as a 4-2-1 design  . The specification of his/my exhaust manifold is:

. The specification of his/my exhaust manifold is:

|

The manifold is going to be one of the easiest places to gain (or lose) power, so I considered it an area where cost cutting should be avoided.

|

The manifold fits to the engine using special compression washers/gaskets which are made of copper and are 44mm in diameter. These cost £3.23 each + VAT from Orwell Motorcycles  (part no. 4FM-14613-00). The engine comes with 8 studs and a custom bracket was fabricated to bolt the manifold to the engine using the these studs and their associated 8mm nuts. The nuts are torqued up to 20Nm (14lb-ft).

(part no. 4FM-14613-00). The engine comes with 8 studs and a custom bracket was fabricated to bolt the manifold to the engine using the these studs and their associated 8mm nuts. The nuts are torqued up to 20Nm (14lb-ft).

Catalyst

There is no getting away from it, I'm going to need to fit a catalyst to meet the SVA emissions requirements. My plan is to use my 2002 R1 exhaust (with internal catalyst), which combined with a Power Commander, should get me through the SVA test.

With hindsight:

I should have spent a lot more time worrying about the emissions before my SVA test. The R1 exhaust and catalyst is simply not going to get this engine through the emissions test and I ended up borrowing a much larger catalyst.

Silencer

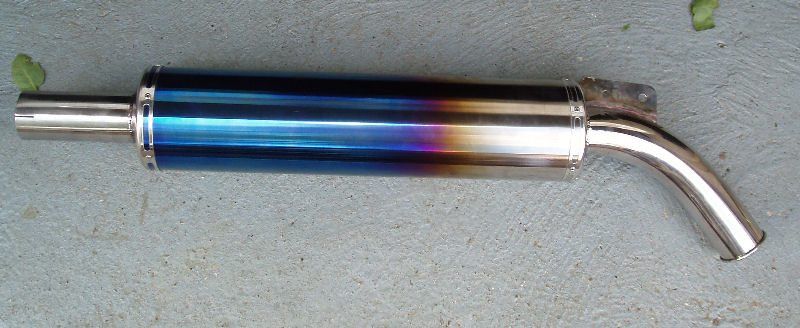

Richard  used a standard R1 silencer which was very effective and met SVA and trackday requirements. He cut the link pipe off and had an adapter made by Competition Fabrications to adapt the 65mm inlet down to the 2" manifold. This is very neat as it fits into the silencer and allows it to sit as far forward on the manifold as possible. R1 silencers are made of titanium, which is expensive to have welded and requires special welding rods to weld it to a stainless steel exhaust system. The 2002 model I have has a small catalyst in it. Compared to bespoke exhausts available it is heavy.

used a standard R1 silencer which was very effective and met SVA and trackday requirements. He cut the link pipe off and had an adapter made by Competition Fabrications to adapt the 65mm inlet down to the 2" manifold. This is very neat as it fits into the silencer and allows it to sit as far forward on the manifold as possible. R1 silencers are made of titanium, which is expensive to have welded and requires special welding rods to weld it to a stainless steel exhaust system. The 2002 model I have has a small catalyst in it. Compared to bespoke exhausts available it is heavy.

With hindsight:

I should have spent a lot more time worrying about noise levels before my SVA test. I had a noise meter but not enough time to check it. This is one thing that you can do little about on the actual day of the test.

Silencer Tailpipe

The R1 exhaust doesn't have a tail pipe that takes it outside of the bodywork so this has to be added. The R1 silencer has two concentric outlet pipes at 42mm and 60mm diameter. The inside pipe is not easily accessible so I'm going to have to fit a fat tail pipe, which will need to be radiused at the end for the SVA test. The R1 exhaust weighs 4525g.

Messing about with an R1 can is a waste of time as the tail pipe caused me no end of issues, before finally failing completely. Spend a bit more money and get a decent exhaust that will fit nicely. This new exhaust weighs 2445g.

Silencer Mounting

When mounting the silencer it must not be parallel to the chassis rail or it will not fit in the side pod. The silencer is usually mounted with a degree of flexibility, usually using a rubber bobbin  . These cost about a quid from Halfords and other auto stores.

. These cost about a quid from Halfords and other auto stores.

It is important that the mounting design results in compression forces on the bobbin and not sheer forces. Bobbins are not designed to work with high sheer forces or under tension, and will fail prematurely. It's amazing how many people mount exhausts without bearing this in mind. The silencer has a suitable mounting tab on it already. The bobbin is 34mm in diameter and 22mm high, with 5/16" UNF studs on each end. Make sure they come with the required nuts or you will have to source them seperately.

I'm going to have to fabricate a suitable mount for the bobbin but I notice that The Kit Car Workshop  sell one.

sell one.

Exhaust Wrap

It is not desirable to wrap the exhaust as it can cause localised hot spots. The recommended approach is to line the sill inside with heat reflective material. I got mine from Rally Design  .

.

Heat Shield

Some people also fit a heat shield into the side pod and I may consider this, given the catalyst can get very hot. Either way, I'm going to put some temperature recording strips inside the exhaust sill, to monitor how hot it gets in there.

SVA Test Requirements

Not only must the exhaust meet the noise requirements but any exhaust extending out beyond the bodywork must have radiused edges (3mm). Most people seem to get round this by cutting the exhaust flush with the bodywork so that it doesn't extend outside and by making sure there are no sharp edges.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © Robert Collingridge 2004 |

|

|

|

![]() (part no. 4FM-14613-00). The engine comes with 8 studs and a custom bracket was fabricated to bolt the manifold to the engine using the these studs and their associated 8mm nuts. The nuts are torqued up to 20Nm (14lb-ft).

(part no. 4FM-14613-00). The engine comes with 8 studs and a custom bracket was fabricated to bolt the manifold to the engine using the these studs and their associated 8mm nuts. The nuts are torqued up to 20Nm (14lb-ft).

![]() sell one.

sell one.