Fuel pump and filter fitted:

- Fuel pump wiring.

- Need to fabricate pump and filter mounts.

And all before Christmas!

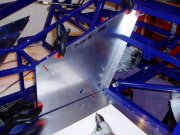

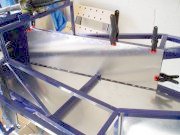

Rear Bulkhead Panels

Finished drilling the drivers side panel. Started modifying the passenger side to fit, using the same approach. Drilled out the holes and then cleaned up both panels for powder coating. I wondered on the best approach to clean the panels up for powder coating. In the end, I filed the edges smooth and then polished them up with P400 wet and dry paper. I'm working on the basis that the powder coat will fill in any fine scratches, resulting in a smooth surface finish.

Handbrake

|

I fitted this to the car to get it out of the way.

|

Handbrake Cable

|

While I was playing with the handbrake I thought I'd fit the cable too. This has to go in the right way, with the adjuster in the bottom cable slot. It's a 6mm x 25mm bolt to fix the cable to the handbrake.

Whilst I was fitting this I noticed that the cable will rub on the chassis where the tunnel narrows (circled in linked picture). I'm not sure if this will be a problem at SVA time.

|

Centre Tunnel Top Panel

|

Fitting the handbrake distracted me on how best to fit the panel over/around it so I cut a cardboard template from the supplied panel. I measured where the handbrake would need to sit and its likely travel. I cut a slot in my template and checked it aligned. This surfaced one issue. The button end is wider than the rest of the handbrake, so I'm going to need a 20mm diameter hole at one end of my slot to thread the panel over the handbrake.

|

Powder Coating

Arranged to meet my local powder coating workshop tomorrow.

2nd November

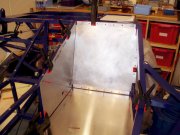

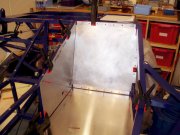

Centre Tunnel Top Panel

|

Having checked the cardboard template worked I mapped the template markings across to the supplied panel, drilled out the 20mm hole and the cut the slot. I plan to replace this aluminium panel with a carbon fibre one at a later date, so I'm using rivnuts to hold it in place. This will also make access easier later. I also had to bend the rear edge of this panel slightly to fit the chassis rails.

|

Fixing rivnuts are something else I've never done before. For this panel I'm using six of them (5mm thread, 6.8mm diameter) and I drilled the usual 3mm pilot holes through the panel and chassis rails. I drilled the panel out to 5mm and cleaned and polished it up for powder coating. I opened the holes in the chassis rail to 7mm and fixed the rivnuts.

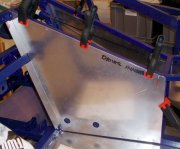

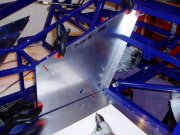

Drivers Rear Tunnel Panel

|

This panel has to be fitted before the bulkhead panel as the folded part goes behind the bulkhead panel and the two are riveted together. The holes also need to be cut for the seat belt mounting points. This panel needs some modification to clear the chassis rail across the rear bulkhead.

Having got the position right, I held it in place with two 3mm drill bits in pilot holes and some clamps. It took a long time to get it to sit right and to cut and file around the chassis rail and welded joints. The next challenge was to cut the holes for the harness mounts to show through. I wiggled a pencil round and round, through the mounts and this left a circle on the back of the panel indicating where to make my 22mm holes. I then removed the panel and tidied it all up, ready for powder coating.

|

On the face of it, I haven't achieved much in my mornings work but I'm taking my time to do it right. I only want to do this bit once! I can't see how people can avoid powder coating the panels though. I've been as careful as I can but they have loads of marks on them, which I'm going to have to polish out.

Powder Coating

Packed up all my bits and panels into the car and went to visit my local powder coating workshop, which is conveniently next to my site of work. I got a quote to do all of the panels and bits I need doing and left the uprights, steering rack mounts and paddle shift with him to do this week. I'll leave all the panels with him when I've completed them all. I showed him a few and he thinks I need to do some more polishing :-( They will also need an acid etch primer before powder coating. He also gave me a demonstration of the process, which was interesting.

For use with black panels you can also get black rivets but I want to use the normal ones.

3rd November

My plan was to run some brake pipes but I got as far as fitting the rear T-piece on the chassis rail above the differential, using a 6mm rivnut and bolt. I need a special tool to cut the pipes which I won't have until next week. I then got curious about what would be unreachable once the rear bulkhead panels had been fitted and ended up putting the lower rear wishbones on the car. The bolts have to go through the mounts the right way or you will never be able to get them off again (without removing the bulkhead panels). Having tie-wrapped these up out of the way, I got thinking about the outlets on the fuel tank, so I trial fitted this in place with some roof straps. I noticed that all the inlets and outlets are already clear and do not need to be drilled through.

|

I'm also missing an adaptor fitting for the tank fuel return line. I ordered another one from The Kit Car Workshop  . .

|

|

The tank is a really odd shape with a trapezoidal side profile. Don't know why this is the case. It's going to make fabricating the tank fixing straps interesting.

|

One thing led to the next and I started to think about how the differential would fit in through all the chassis rails. And that led me to ...

Differential Fitting

Every piece of advice I've ever heard or read says that fitting the differential is a two-man job. It weighs about 20Kg and is an awkward shape. Firstly, I wrapped all the chassis rails that might get damaged. The best thing to use for this is old jiffy bags. They don't tear and provide very good padding. My car is on trestles, about 1m off the ground so I climbed underneath and lifted the diff up through the hole and rested the front on a padded rail. I used a roof strap to hold the back end in place, whilst I climbed back up. From above I twisted it 90° to get the sides in through the hole, then back to the right orientation. It sounds easier than it really is! I then quickly put the long bolt in place to secure it roughly in place. Not a scratch on the powder coat!

|

This next bit took me the best part of the evening. The new 2006 chassis has different fitting to those I've seen on earlier Fury's. It has the long 10mm x 240mm bolt going across the top but, there are two spacers for the lower front holes and a 10mm bolts goes through an extra hole in the 6-point harness mount. Finally there is a rear tube welded on the chassis for the rear 8mm bolt.

|

Fitting the long bolt was relatively easy but the two lower ones were a nightmare, compounded by the fact that the set of bolts supplied to fit the differential are obviously for the 2005 chassis and these two bolts were missing. I had some suitable ones to hand but fitting them took ages. I used thread locking compound as I don't want this flapping about with 160+bhp going through it.

5th November

Fitted the front suspension lower wishbones to get them off the floor and out of the way. These can't be fully tightened up until the car is on the floor since the rubber bushes need to flex away from their 'at rest' point (and not sit under tension) and this can't be done until the car is on the floor. I also can't get right ball joint to go in to the wishbone more than 10mm. I'll try swapping them over as the left one goes in all the way (about 50mm). The amount by which these are threaded in or out is used to set the camber (which also can't be done yet).

6th November

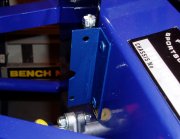

Brake Fluid Reservoir

|

Made a 90° bracket to mount the brake fluid reservoir to the footwell as the additional spare (sealed) outlets get in the way. I made this up from some aluminium angle and painted it to match the powder coat. Riveted it to the end of the drivers footwell.

|

Painted steering column extension with black Hammerite smooth. Swapped the front ball joints over and with a bit more force, managed to get them both to wind in properly. It seems the threads on one ball joint are larger/tighter than the other.

Passenger Front Outer Panel

I thought that the outer panels would go inside of the chassis to hide the rails and provide a cleaner finish inside the car but, it is clear that they are designed to go on the outside of the chassis rails and Martin confirmed this for me. Either way the rear tunnel panels are going to need some work to make them fit. The advantage of fixing them to the outside of the car is that the harness mounts are exposed. The downside is that the side impact protection means some serious template work is required to get them to fit. I'm going to put them on the inside of the chassis because I think it will look better, especially since my panels are going to be powder coated.

7th November

Brake Fluid Reservoir

|

Fitted the brake fluid reservoir using 5mm bolts and nylocs and plumbed it up to the brake cylinders. Made the mistake of undoing one of the hose clamps to ease it up the rubber hose. Once they are undone, they are a nightmare to get back together.

|

Drivers Front Outer Panel

|

Having decided to fit the outer panels on the inside of the chassis, I started by having a look at the drivers front side. This panel needs to be modified as a chassis rail goes across the car midway along it. This one also needs a bit more work though as it is too long and the front edge also needs modifying to get the right angle on it. The rear edge will overlap with the rear outer panel (this one on the outside) and where they overlap the rivet holes will have to be drilled through both panels at the same time.

|

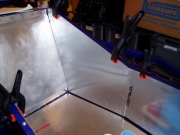

Drivers Rear Outer Panel

|

Putting this on the inside of the chassis is going to make fitting it a easier. The downside is that the additional length now has to be folded out of the way though, to fix to the rear chassis rail. The only way to see how this might work was to cut a cardboard template out using the supplied panel. I then cut this to fit around the various chassis rails and to see where the fold needs to be made. This panel will also need holes cut for the harness mounts.

I've never folded sheet aluminium before and all I had to do it with was some lengths of hardwood, some clamps and a large hammer. As it happened, it worked out really well and I'm very happy with the finish. With the fold made, I drilled some pilot holes to hold the panel in place whilst I then marked up the remaining modifications required. It's only when you have all the panels in place that you can check they all go together as planned.

|

8th November

Drivers Rear Outer Panel

Finished off this panel. Drilled out the holes to 5mm. Cleaned up the panel and polished out any marks. I've already drilled the holes through the rear bulkhead panel and through the chassis. These are now blind, behind this panel but I've got to drill through it to match. I didn't think about this at the time. I carefully marked up the panel alignment on the back so that I could drill matching holes with the panels out of the car. I did a test hole top and bottom first and then used this as a guide for the others.

Drivers Front Tunnel Panel

|

The last panel to do on this side of the car! I'll be glad when the paneling is over. I'm not sure if I'm working very slowly or just being very thorough but, the paneling seems to be dragging on a bit! This panel is flat but has to mount onto a set of non-parallel chassis rails. This means that although the panel has a straight edge and mounts onto straight rails, it needs modifications to get a nice even finish. I clamped it and drilled two pilot holes. In centre punching the rivet holes, the panel actually gets bent to fit the compound shape required. This one also overlaps a rear panel, on the outside.

|

On the face of it, not much has been achieved for a whole mornings effort but I've now finished all the drivers side panels. I've deburred them, polished them, cleaned them up and they are all wrapped up in bubble wrap to go to the powder coaters. There is about as much work as I expected to panel a Fury but, it is just taking so much longer than I expected. My target of getting the engine going before Christmas is looking optimistic.

A colleague at work has just got his R1 Striker back from the exhaust manifold fabricators. He used the same company that I plan to use. He is very happy with the work they have done for him, which bodes well. I've got some aluminium on order to fabricate my silencer mount and fuel tank brackets.

Drills & Drill Bits

I've been drilling 3mm pilot holes for all the panels so far and then enlarging them out to 5mm. Swapping bits would have been a right pain if I didn't own two electric drills. Drilling a centre punched panel with a 3mm bit is also much safer than going straight to 5mm. I also use a cordless one with a countersink for deburring. I've used five 3mm drill bits so far and I've kept the blunt/broken ones as locating pins to the hold panels in place. I've wrapped the (sharp) ends of the old ones with red tape so I don't try to re-use them. Because the brunt of the drilling has been done with 3mm drill bits, my original 5mm drill bit is still going strong.

For the 22mm holes around the harness mounts, I've used a round hole saw. I'm sure this was designed to cut wood but it makes a good job of cutting holes in thin aluminium sheet, though it does get very hot!

I've got two full-face head guards in my garage (from Screwfix) so that there is always one to hand. These are cheap (£8 each) and comfortable and they keep your face looking the way it was meant to be.

9th November

Bugger! Found a 'small leak' in our ensuite bathroom, which seems to have been there for a while. Slight pause in progress whilst my attentions turn to completely gutting, re-flooring, plastering, tiling and fitting a new bathroom suite :-(

10th November

Spent the whole day working on the bathroom. My bits are ready to be collected from the powder coaters and my pieces of aluminium have arrived.

11th November

Picked up my powder coated parts. They look fantastic, especially the paddle shift. The front uprights look like new and finally getting the steering rack mounts mean I can now progress the front suspension installation.

|

Fitted the steering rack using 8mm bolts.

|

13th November

Trial fitted the front uprights and Nitron springs and dampers. Also looked at the front brake disks and hubs. This resulted in an order to Namrick to get all those nuts, bolts and washers I need to complete a number of outstanding jobs.

14th November

Rocker Arms

|

I'm still waiting on some washers from The Kit Car Workshop  . The washers need to go at the front and improve the self-centering action. Post SVA, the washers are moved to the rear of the car to improve the handling. I fitted some grease nipples into these so that I can inject them with grease to keep water out. The grease nipples are self tapping and required a 15/64" pilot hole, before being screwed into the rocker arm. . The washers need to go at the front and improve the self-centering action. Post SVA, the washers are moved to the rear of the car to improve the handling. I fitted some grease nipples into these so that I can inject them with grease to keep water out. The grease nipples are self tapping and required a 15/64" pilot hole, before being screwed into the rocker arm.

|

15th November

Steering Column Extension

|

I fitted this to make sure the steering rack was centred, so that the steering wheel will turn the same amount in both directions. With it centred I can then check that the uprights are facing in the right direction. I tried to fit it and realised I had made a mistake somewhere. It seemed to be too long and it rested on a chassis rail. I had to move the steering column end plate (bolted to the end of the footwell) up about 10mm to get it to fit correctly.

|

Steering Wheel

I fitted and centred the steering wheel. This also proved that the rack is 2.4 turns lock to lock.

Front Uprights

Before these can be fitted, the upper ball joint needs to be screwed into them. I used Castrol CL grease (low temperature, salt/water resistant) and there is a round locking plate which needs to go on first. You need a 46mm wrench to tighten them. This is bolted to the rocker arm, again using a locking plate.

How do you stop the ball joint rotating whilst you tighten it? The approach I used was to wedge it in hard so that it gripped when tightened. What torque should it be done up to? Not sure yet.

The downside of putting the front uprights on, is that my car is now a lot wider and I had to reorganise stuff in the garage to get around the car more easily. Without the springs/dampers in place the suspension arms will droop under the weight of the uprights. These extreme angles can damage the ball joint rubbers. To hold the suspension arms in place horizontally, I loosely fitted the spring/damper bolts in place and used some cargo straps between them.

Lower Ball Joints

I trial fitted these a few days ago. The lower ball joint is also used to adjust the camber (lean in/out of the front wheels). I estimated this using a spirit level as I am going to get it set up properly by The Kit Car Workshop  . The front suspension camber angle should be between 0.75° and 1° negative. This means the wheel is sloping in at the top slightly. Changing the position of these is going to change the toe in/out.

. The front suspension camber angle should be between 0.75° and 1° negative. This means the wheel is sloping in at the top slightly. Changing the position of these is going to change the toe in/out.

Front Brake Disks

These have to be bolted to the front hubs before the hubs can be fitted. The disks weigh 3035g each. This is a little bit heavier than I expected and I notice that the ones Chris  fitted had larger cut-outs to reduce the weight further. The disks bolt to the hubs using four 10mm bolts and some thread locking compound. They should be torqued up to 50lb-ft which is a lot. I also used some Copper Ease on the mating surfaces.

fitted had larger cut-outs to reduce the weight further. The disks bolt to the hubs using four 10mm bolts and some thread locking compound. They should be torqued up to 50lb-ft which is a lot. I also used some Copper Ease on the mating surfaces.

Front Hubs

|

My front hubs came with the inner bearings pre-fitted by The Kit Car Workshop  . They weigh 1380g each. I packed the hubs with Castrol LM grease (high temperature, for wheel bearings). The hub nuts (26.8mm) are tightened to 27lb-ft whilst spinning the hub anti-clockwise to seat the taper bearings and then backed off by 90° according to the Haynes manual but, this is a subjective thing and I tightened them and then backed off the nut until they felt right. I will check them again later. A castellated sleeve and split pin hold it all in place. I needed to use the washer, hub nut and sleeve from my old hubs but I used a new split pin. The old hub nut dust covers would not fit my pattern alloy hubs so I've left them off. My CRX wheels have dust covers which will have to do. . They weigh 1380g each. I packed the hubs with Castrol LM grease (high temperature, for wheel bearings). The hub nuts (26.8mm) are tightened to 27lb-ft whilst spinning the hub anti-clockwise to seat the taper bearings and then backed off by 90° according to the Haynes manual but, this is a subjective thing and I tightened them and then backed off the nut until they felt right. I will check them again later. A castellated sleeve and split pin hold it all in place. I needed to use the washer, hub nut and sleeve from my old hubs but I used a new split pin. The old hub nut dust covers would not fit my pattern alloy hubs so I've left them off. My CRX wheels have dust covers which will have to do.

|

Front Top Tunnel Panel

|

It's about time I got on and finished the paneling. They are due to be powder coated next week. I started with an easy one to ease myself back into it :-)

|

16th November

Torqued up steering column bolts.

Camber Adjustment

Torqued up the upper ball joints on the front uprights. Tried to adjust the lower ball joints to get a camber approaching the 1° negative but when wound fully in, the camber wasn't even close. The only way I can see that I could get to this angle is to cut down the lower ball joint threads. I need to check this with Martin before I take such a drastic action.

Started looking at fuel tank straps and rear uprights.

17th November

Picked up a brake pipe flaring tool from my work motor club.

|

With my various fixings delivered by Namrick I can now put together a few more things like my paddle shift lever.

|

I also started work on my fuel tank mounting straps as the foam arrived from NF Auto.

18th November

Bought a vice as I one to hold the brake pipe flaring tool in and it should make bending the fuel tank straps easier.

22nd November

Differential

Replaced the bolts on the differential for more suitable ones from Namrick. The ones supplied were for the 2005 chassis. The lower front bolts are 10mm and 70mm long on the passenger side and 50mm on the drivers side. This was the start of today's problems.

The rear bolt on the differential in particular is a right pain to get in. The chassis mount and the differential simply do not align with the other bolts in place. I'm going to have to use some brute force to get this bolt in but so far all attempts have failed. Until this bolt is in, I can't put the petrol tank on.

Having wasted a decent part of the morning on this, I need to get back to the paneling ...

Rear Tunnel Top Panel

This panel is also held on by bolts into rivnuts. My countersunk 5mm rivnuts arrived last week so I fitted these all in place. They need a 6.2mm hole (¼" drill bit). I also used some Waxoyl down the holes first, to trap any swarf in place. I used a tiny bit of permanent thread locking compound too, to ensure these don't slip. The trick with the rivnuts is to not over tighten them or you will strip the threaded part. If they are too loose, you can go back and tighten them up with the rivnut tool.

|

The front end of this panel overlaps the centre tunnel top panel. The time consuming part is tidying up and polishing the panels, ready for powder coating.

|

Rear Differential Bolt

If I do one thing today, it is going to be this bloody bolt! Removing the long top bolt seemed to be the only way to go so I also loosened the two front bolts. Using a piece of had wood as a lever I managed to get the rear bolt in and after a lot of messing about, the top bolt back in too. 11pm and it's finally done!

23rd November

It feels like a lot of time has passed since I did the panels on the drivers side.

Passenger Rear Tunnel Panel

|

This panel has to be done before the rear bulkhead as it folds behind it. It needs holes cut for the harness mounts.

|

Passenger Bulkhead Panel

|

I have done this panel already but it needs trimming down to fit now that the above panel is in place.

|

Passenger Rear Outer Panel

|

The additional length has to be folded out of the way, to fix to the rear chassis rail, through the bulkhead panel. As with the other side, I didn't know this when I drilled the holes for the rear bulkhead panel so I'm going to have to align the panels and work out where the blind holes are again.

I cut a template again using some card sheets. I cut the template to fit around the various chassis rails and welds and to see where the fold needs to be made. I also cut holes to expose the harness mounts. My unusual approach to panel folding seems to have worked even better this time and I'm very pleased with the fit and finish.

Didn't manage to quite finish it in this session but, I see an end to the paneling in sight now!

|

Other Stuff

The outstanding parts from my order from The Kit Car Workshop  are probably going to be a few more weeks yet. This makes booking a slot with the exhaust manifold fabricators for this side of Christmas an unrealistic proposition now. I'm going to aim to get as far as I can before Christmas and to book a slot for early January 2006.

are probably going to be a few more weeks yet. This makes booking a slot with the exhaust manifold fabricators for this side of Christmas an unrealistic proposition now. I'm going to aim to get as far as I can before Christmas and to book a slot for early January 2006.

Front Lower Ball Joints & Camber Adjustment

According to Martin, these are going to need to be cut down to get the required camber. These are slightly over long to account for manufacturing tolerances. This is simply a matter of taking them out and sticking them in a vice (with the locking nut on, to straighten any damaged threads as I take it off), to cut them down. By my measurements I need to remove less than 15mm on both sides to be able to get the uprights vertical.

Out of curiosity, I wondered just how accurately can you set this anyway. The granularity of adjustment is one 360° turn of the ball joint, which equates to a movement of 1.5mm (the thread pitch). The distance between the upper and lower ball joint pivot points is about 215mm, so one turn equates to an adjustment of 0.40°.

24th November

Front Lower Ball Joints & Camber Adjustment

Attempted to cut the left ball joint with a hacksaw. I quickly gave up on this though, as it made very little impression. An angle grinder is right up there with a large hammer when it comes to precision engineering tools but, it left a nice clean cut. I adjusted it so that it was the first 360° turn that provided negative camber, as measured with a spirit level on the brake disk and wheel hub. That will do for now.

DD2 Lite

There is a chap on the Sylva Autokits organising a bulk buy discount on the DigiDash 2 Lite unit  . I was originally looking at the DD2 Pro (with data logging) but, this is a good price and an opportunity bring my projected spend back to my original planned budget.

. I was originally looking at the DD2 Pro (with data logging) but, this is a good price and an opportunity bring my projected spend back to my original planned budget.

25th November

Cut the right lower ball joint down and adjusted it correctly.

I kept the old bolts from my Escort uprights and the bolts used to hold the calipers on are not metric. I'm going to need some shorter ones (25mm or 1") for my Hi-spec calipers though as the existing ones go too far through the uprights and would hit the brake disks.

Cut the lengths of fuel pipe to see how it should run along the tunnel. The return pipe looks easy enough but the feed pipe is going to have a more convoluted route due to the handbrake cable and mounts.

Started to look at the radiator mounting and fabricating some mounting brackets from aluminium.

|

Made up a lower mounting bracket, which also doubles up as a mount for the twin horns. Very 'Colin Chapman'.

|

28th November

Passenger Rear Outer Panel

|

Finished this off and tidied it up for powder coating.

|

Passenger Front Outer Panel

|

This panel needs to be modified as a chassis rail goes across the car midway along it. The rear edge will overlap with the rear outer panel (this one on the outside) and where they overlap the rivet holes will have to be drilled through both panels at the same time. I had to file the top down quite a lot to get it to nicely follow the contour of the upper chassis rail.

|

Passenger Front Tunnel Panel

|

This panel is flat but has to mount onto a set of non-parallel chassis rails. This means that although the panel has a straight edge and mounts onto straight rails, it needs many modifications to get a nice finish. I clamped it and drilled two pilot holes. In centre punching the rivet holes, the panel actually gets bent to better fit the compound shape required. This one also overlaps the rear outer panel (on the outside).

|

Panels All Done!

With the panels all done now, I gave them one last polish and check over before wrapping them up in bubble wrap to go to the powder coaters. And I thought I could do all the panels in three days! Now I can get on with the fun jobs and make some real progress and also start to make this thing look like a car.

Lessons learnt from paneling the car (assumes panels on the inside):

- Tape cardboard to the floor to protect it, as you will drop things and rest tools on it.

- The most frequently used tool in my garage was probably my Draper 69390 wet & dry vacuum cleaner.

- Cut cardboard templates to make sure you cut and fold panels in the right place.

- Use a couple of 3mm pilot holes and old 3mm drill bits to lock the panels into alignment whilst you drill the other holes.

- Having two or more drills speeds things up considerably (one with 3mm bit and another with a 5mm bit).

- Make sure you put the rivets in places that can be reached with the drill and a pop riveting tool.

- Use a large (>12mm) drill bit wrapped in tape, to debur holes. Countersinks typically have too steep an angle for use in aluminium.

- Use plenty (>10) of plastic clamps to keep things in place whilst you work. These don't mark and provide a decent grip.

- Use wide-flange rivets and clamp onto the flanges to hold panels in place, whilst you work around them.

- Start with the rear tunnel panels, because they fold behind the bulkhead panels.

- Don't mark and drill the front edges, because the front panels overlap them.

- Mark and drill the rear bulkhead panels next but only drill top and bottom edges, because the rear outer panels fix to them.

- Rear outer panels next because they need to be bent to fix to through the rear bulkhead panel and they underlap the front panels.

- Front tunnel and outer panels, because they overlap the rear panels.

- Do the tunnel top panels last. Use rivnuts on centre and rear panels as you may want to get access later.

- I probably put too many rivets in the floor panels. I had no advice to go on, so I played it safe.

- Allow 5 full (>8 hours) days to complete the paneling.

- I can't see how this job can be done without marking the panels, as mine came with no protective film. I polished them up as best I could with P400 grade wet and dry paper, and worked on the basis that they would be powder coated to hide any fine scratches.

30th November

Dropped all my panels off at the powder coaters to be done in gloss black. Also picked up some bolts for the front calipers.

HiSpec Front Disk Calipers

|

These bolt to the front uprights and need to be centred on the brake disks (use washers to achieve the correct spacing). Mine fitted perfectly when bolted straight to the uprights. These M12 x 25mm bolts are torqued up to 110Nm. My old caliper locking plates are a bit of a mess and I don't know where to source new ones from. I'll worry about this later.

|

Next month

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © Robert Collingridge 2004 |

|

|

|